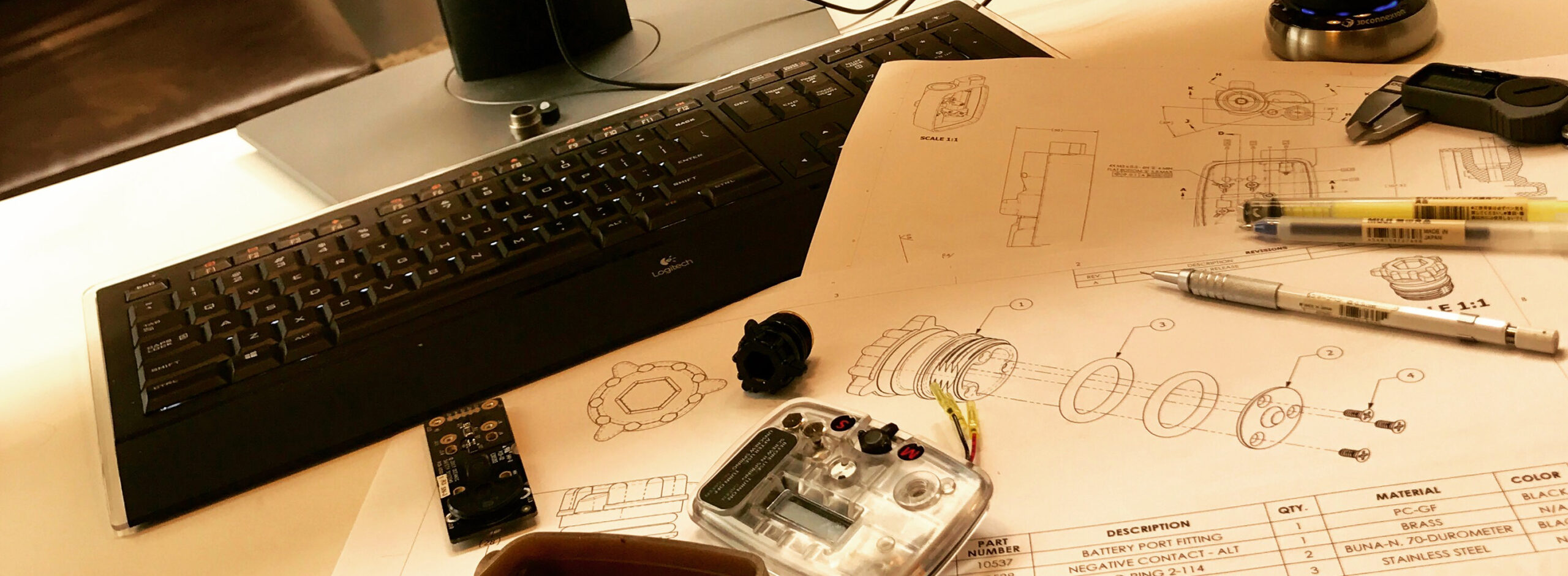

Product R&D

What will it do?

Projects Don’t Go Wrong…They Start Wrong.

An observed problem. A seed of an idea. A question about whether a

solution could be invented. This is the beginning of product R&D.

Experts in:

- Concept generation

- Ideation

- Specification development

The first question we ask about a product concept is what it needs to do. Product R&D begins with a problem in the market: a common workaround, a product that experiences the same failure over and over, or a safety issue that plagues an industry.

How the problem will be solved is the question engineering solves at this stage.

To do this, sound requirements are critical: we get to the bottom of your business needs, your user needs, and the needs of the product itself to build the right foundation. We sort aspects of the concept into musts, wants, and nice-to-haves, then prioritize accordingly.

We’re in the business of creating novel solutions. For our clients, “But that’s how it’s always been done” is not a requirement.

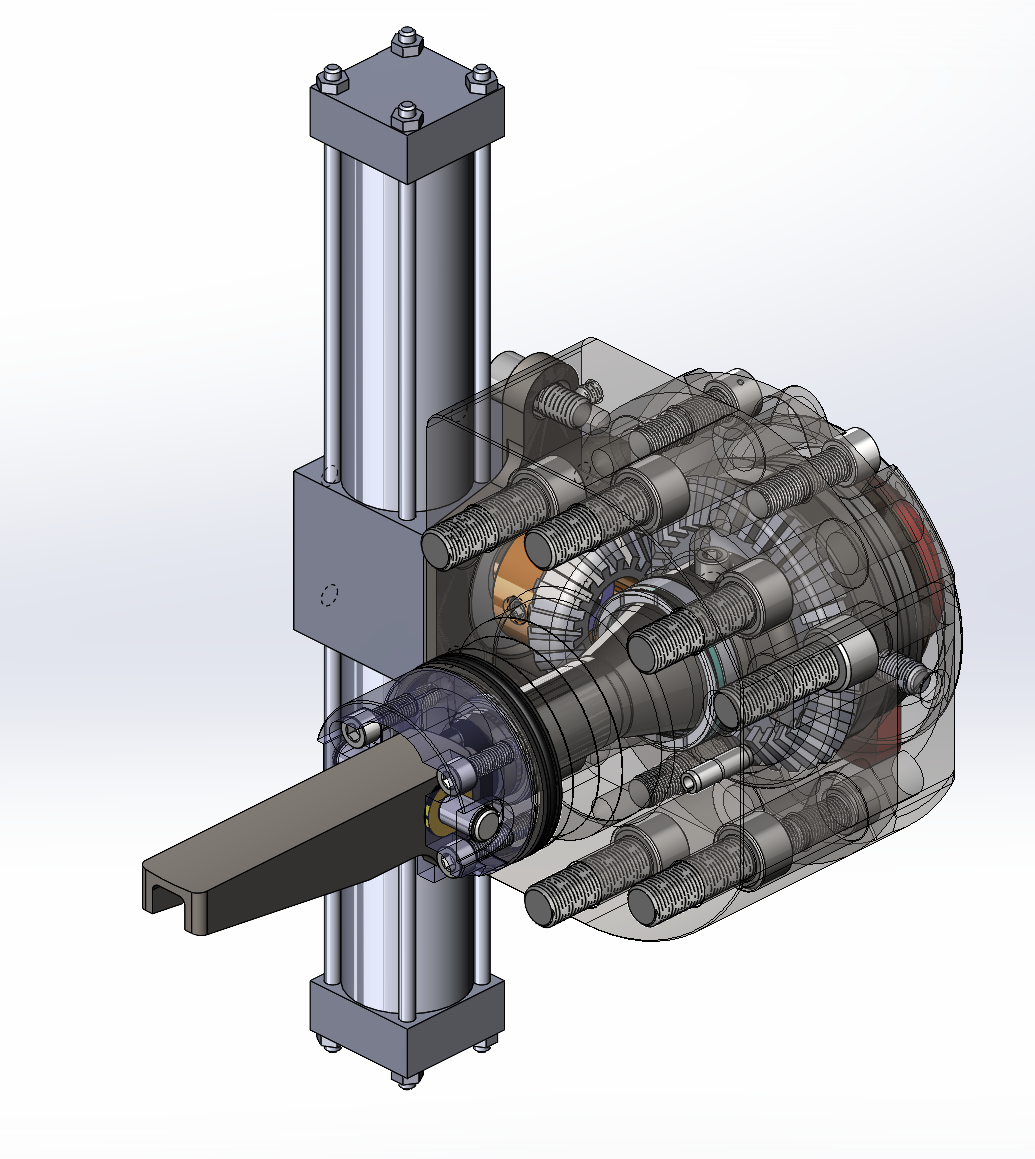

PROJECT FEATURE

Years ago, a client came to us for engineering support after a six-inch piece of metal flew across the shop projected by 20,000psi and blew a hole through a steel door. The tech who had seen it happen found the part in another room, still spinning. Luckily, no one was hurt. The manufacturing process for the part had been refined so the ACME threads were perfect; the resulting lack of friction made the design dangerous.

Despite the perfect threads, this part was the result of a case of ancestor worship. We started our engineering R&D process by learning about the purpose of the part and were told it was a pin-puller and that the client company had “always done it that way.” “But why does it pull a pin?” we asked. After more research, it turned out that the true purpose of the assembly was to release a part. From the beginning of concept generation, we decided to rename the assembly a “part release,” regardless of its final embodiment. This freed us up to develop design concepts that were not only safer, but simpler.

Our client expected us to solve the problem of making the assembly safer to manufacture. We solved the problem of how to more efficiently manufacture the entire assembly.